The Energy Sector’s Push Toward Smarter, More Efficient Operations

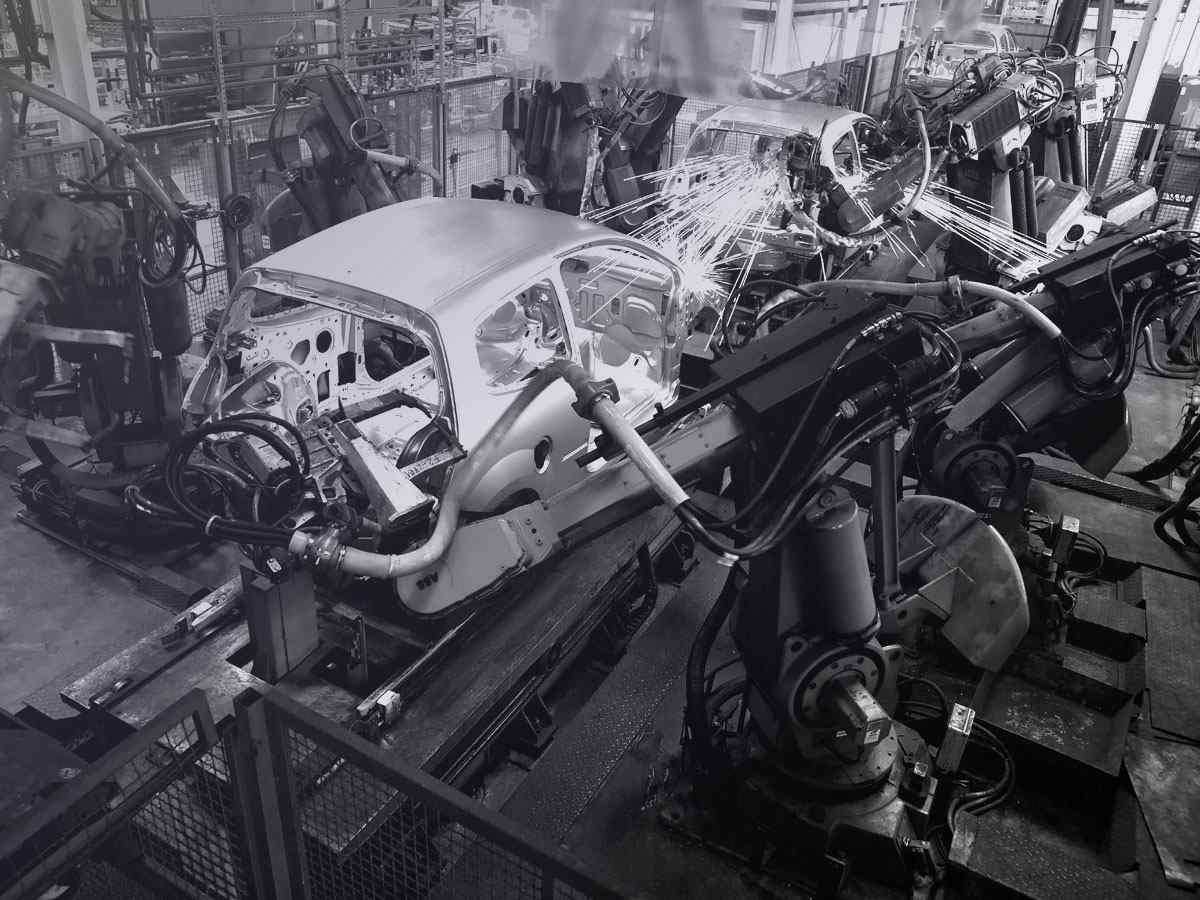

As the oil and gas industry faces mounting challenges—from rising operational costs to unpredictable supply chain disruptions—companies are turning to artificial intelligence (AI) and automation to enhance efficiency, minimize downtime, and ensure long-term sustainability. Traditional approaches, reliant on manual processes and reactive maintenance, are no longer viable in a fast-evolving energy landscape.

With expertise in engineering, procurement, and construction (EPC) as well as modular refinery deployment and supply chain management, SRG is integrating AI-driven solutions into its projects, leveraging automation to improve refining efficiency and reduce operational risks.

By incorporating real-time predictive analytics, AI-powered monitoring systems, and automated process optimization, SRG is driving a technological transformation in field operations, refining, and logistics—enhancing decision-making, reducing waste, and improving overall system resilience.

Addressing the Industry’s Key Challenges with Smart Technologies

For decades, oil and gas operations have relied on human-led monitoring, scheduled maintenance, and reactive problem-solving. These conventional methods, while effective in the past, have resulted in inefficiencies, unplanned downtime, and increased maintenance costs.

One of the biggest financial burdens in the industry is equipment failure and unscheduled shutdowns, which can lead to millions in lost revenue per day. Many companies still rely on manual inspections and outdated maintenance models, which often detect issues too late—after damage has already occurred.

In addition, supply chain volatility remains a critical concern. Delays in equipment deliveries, fuel distribution bottlenecks, and geopolitical risks make it increasingly difficult for companies to maintain uninterrupted operations. Without real-time visibility, companies struggle to anticipate disruptions and adjust their logistics strategies proactively.

Recognizing these challenges, SRG has integrated AI and automation into its energy solutions, creating a smarter, more adaptive operational model.

AI-Driven Efficiency in EPC and Refining Operations

SRG has developed and implemented AI-powered monitoring systems and automated process controls to improve efficiency across its refining and EPC projects. These technologies enhance on-site decision-making, optimize refining operations, and strengthen supply chain resilience.

One of SRG’s key innovations is its use of predictive maintenance systems in modular refinery installations. These AI-driven tools continuously monitor equipment health, identifying potential failures before they occur. Instead of relying on routine inspections that may miss early-stage problems, SRG’s system analyzes temperature shifts, vibration patterns, and pressure inconsistencies in real-time, allowing teams to take preventive action.

In addition to maintenance optimization, SRG is using AI to improve refining output and efficiency. By integrating machine learning algorithms into its modular processing units, the company has reduced energy consumption by 10% while increasing fuel yield by 5%, resulting in cost savings and improved sustainability.

SRG is also incorporating AI-powered logistics optimization into its supply chain operations. Through real-time tracking and demand forecasting, the company ensures that crude oil, refined products, and essential equipment reach their destinations without costly delays.

At a modular refinery deployed in a remote location, SRG implemented a fully integrated AI-driven monitoring system to optimize performance. The refinery had previously faced unexpected shutdowns due to overheating issues in its heat exchangers, causing delays in fuel processing and increased maintenance costs.

By leveraging AI-powered predictive analytics, SRG’s system detected minor irregularities in temperature fluctuations, which manual inspections had previously overlooked. The AI flagged these deviations, allowing on-site engineers to implement corrective measures before equipment failure occurred.

The impact was immediate. Unplanned downtime was reduced by 60%, and maintenance costs dropped by 25%, allowing the refinery to operate at peak efficiency with minimal interruptions. Additionally, process automation adjustments improved refining efficiency by 7%, maximizing fuel output while reducing overall energy consumption.

This case underscores how SRG’s integration of AI and automation is redefining oil and gas operations, driving efficiency gains while enhancing system reliability.

The Future of AI-Driven Oil and Gas Operations

As AI and automation continue to advance, their applications in oil and gas will extend beyond refining and maintenance. Companies that integrate smart decision-making, automated drilling systems, and AI-powered logistics forecasting will lead the next phase of industry innovation.

SRG is already exploring new AI applications for remote monitoring, enhanced cybersecurity for industrial networks, and automated risk assessment tools to further optimize energy infrastructure. The goal is to create a fully interconnected, data-driven ecosystem that enables oil and gas companies to anticipate challenges, reduce costs, and improve sustainability.

With an AI-powered approach to EPC, refining, and logistics, SRG is not just keeping pace with industry advancements—it is setting a new benchmark for efficiency, reliability, and technological innovation in oil and gas operations.